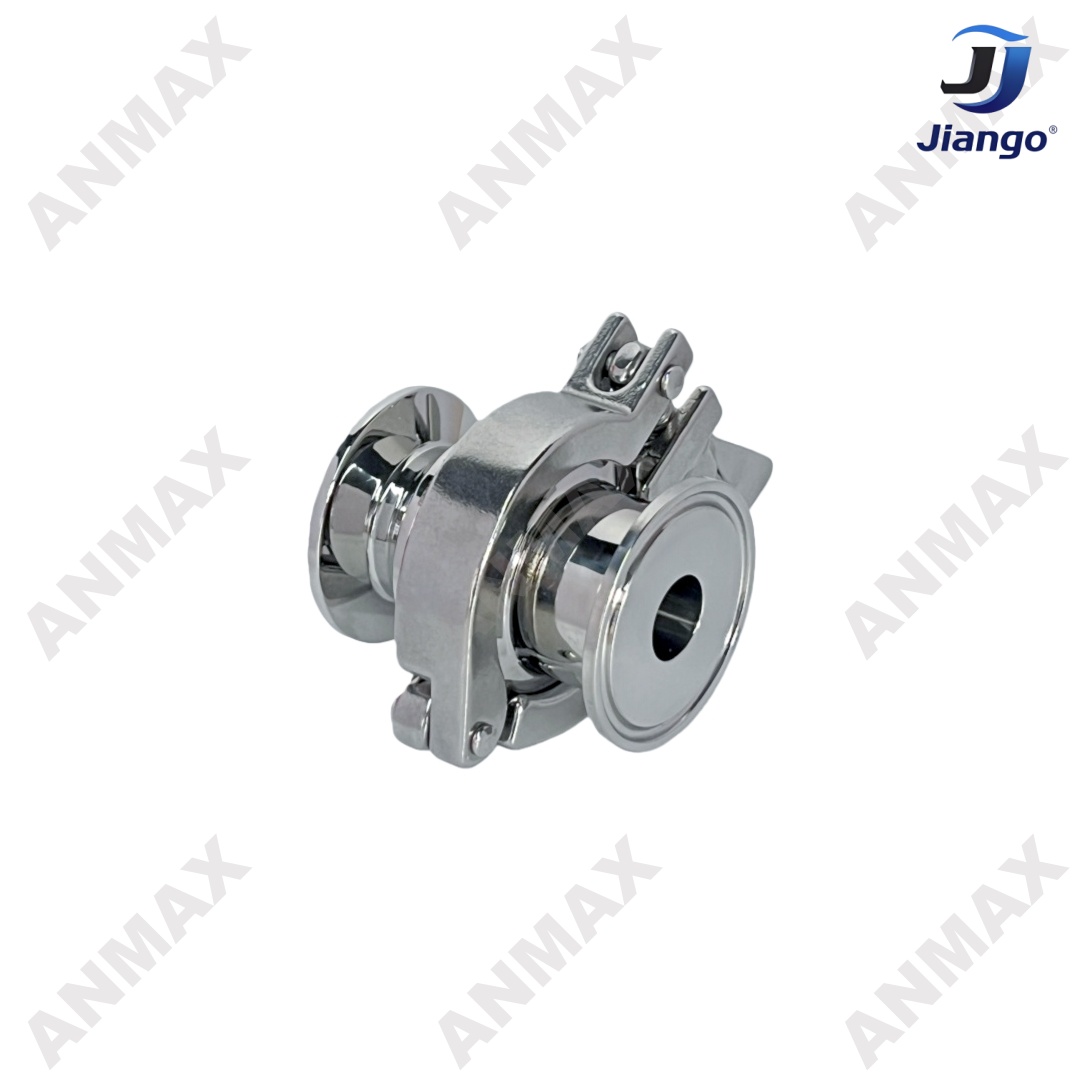

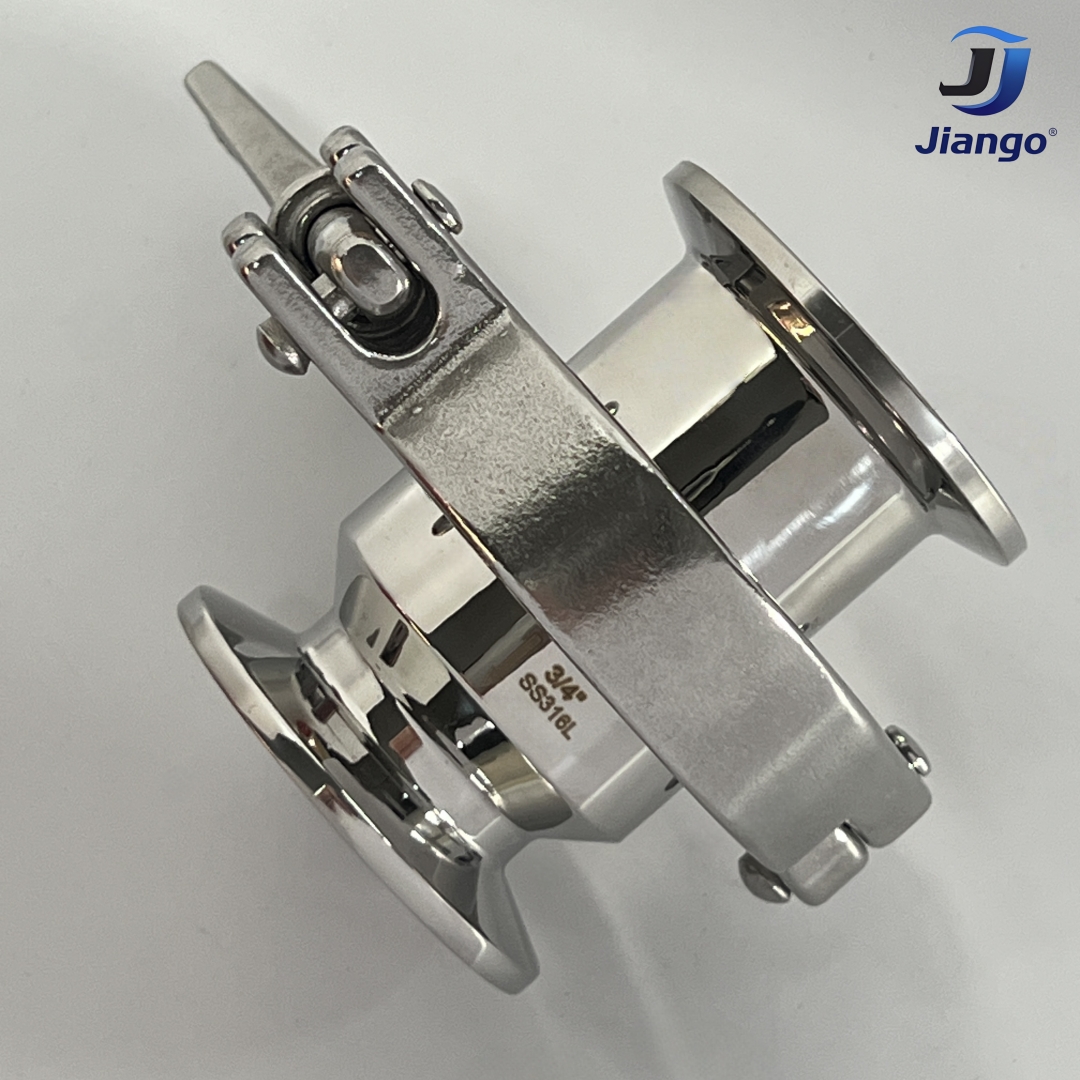

Sanitary Balanced Pressure Thermostatic Steam Trap

Material : Stainless Steel 316L

Size : 1/2”,3/4”,1”(DN15,DN20,DN25)

Connection : CLAMP

100% tested and inspected

Clean steam trap is an automatic valve that filters out condensate and non-condensable gases (such as air) while preventing vapor from escaping.

It automatically opens, closes, or regulates, and discharges condensate once it forms in an energy-efficient manner.

Working principle

At system start-up, the thermostatic bellows remains open to release trapped air, non-condensable gases, and low-temperature condensate.

As steam reaches the trap, the rising temperature causes the bellows to expand and close the valve.

When cooler condensate accumulates around the element, the bellows contracts, lifting the valve from its seat to continuously discharge condensate.

|

Name |

Sanitary Balanced Pressure Thermostatic Steam Trap |

|

Material |

Stainless steel 316L |

|

Size |

1/2”,3/4”,1”(DN15,DN20,DN25) |

|

Standards |

3A / ASME BPE / ISO |

|

Seal |

Viton,PTFE or on request |

|

Max Pressure |

6Bar |

|

Subcooling at Start-up |

2–10°C below saturated steam |

|

Working Temperature |

100℃ ~ +170℃ |

|

Way of Connection |

Welded, Clamped |

|

Package |

Foam bag/shrink bag-carton box-ply woodencase |

Designed for smooth condensate discharge, the fully seamless flow path greatly reduces the risk of bacterial buildup.

Supports self-draining when mounted vertically (outlet facing downward), while also compatible with both vertical and horizontal installation layouts.

The “failure-open” safety design helps avoid unexpected shutdowns, ensuring reliable performance even in demanding conditions.

A large-aperture nozzle allows rapid air evacuation, enabling quick system start-up, reducing blockage risks, and maintaining stable operation.

Hygienic internal structure with no retention areas, optimized condensate drainage, and surface roughness below RA 0.6 μm to effectively prevent bacterial growth.