What is a ball valve?

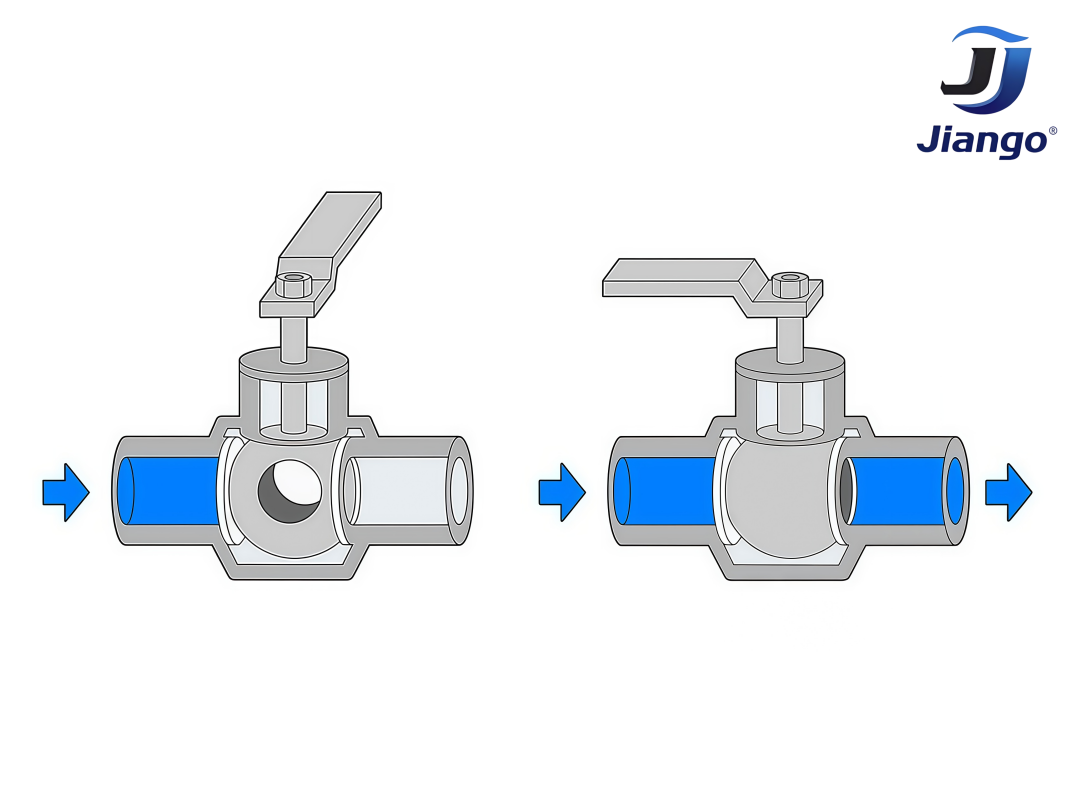

The internal ball is a spherical disc with a central bore.

When the handle is turned, the valve's opening/closing component (the ball) is driven by the valve stem.

The valve disc moves relative to the valve inlet port, allowing the medium to pass through the valve.

When the handle is closed, the ball rotates 90 degrees. When the bore is perpendicular to the pipeline, the opposite action occurs, completely shutting off the fluid flow.

The most notable feature of ball valves is their rapid full-open/full-close operation, making them suitable for regulating and controlling fluid flow.

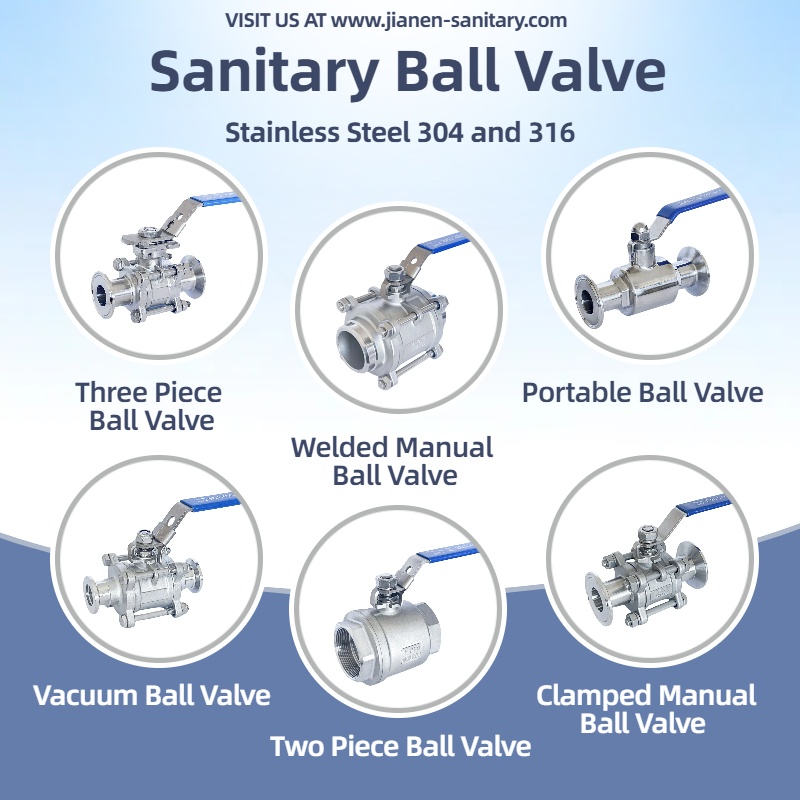

What is sanitary a ball valve?

Sanitary ball valves are made of stainless steel 304 or 316 with standard electronic polishing technology.

Since the ball valves have a smooth surface to ensure cleanliness and no media buildup area,

sanitary food grade ball valve can meet the special requirements of the food and biopharmaceutical fields for a variety of media.

tri clamp ball valve with smooth, seamless, automatic evacuation of manual flow paths are also well suited to the needs of steam field cleaning.

According to your needs, the connection of CIP ball valvecan be threaded, flanged, welded,clamped, ferrule and so on.

Choosing the right connection can improve the quality of your product!

What is the difference between a ball valve and a sanitary ball valve?

Sanitary ball valves can only use stainless steel 304, 304L or 316, 316L stainless steel as the valve body material,featuring a smooth, polished surface,

stainless steel construction and a full-bore design to prevent contamination and allow for easy cleaning

And industrial ball valves have a wider range of valve body materials, materials including cast iron,cast steel, ductile iron, stainless steel and so on.

There are designed for more rugged, less-critical applications where hygiene is not a primary concern.

And industrial valves are generally developed according to the needs of the model,

mainly in the high temperature and high pressure working environment with long service life and flexible operation.

They each have their own advantages and disadvantages, so it is very important to choose the right valve