In today's highly regulated processing environments,

selecting the correct sanitary stainless steel ball valve is critical for ensuring product purity,

operational efficiency, and compliance with international standards.

Selecting the wrong Sanitary Ball Valve can lead to catastrophic failures,

including contamination, unexpected downtime, and costly repairs. This guide outlines the essential features to consider before purchase.

1. Material Matters

The foundation of any reliable sanitary ball valve begins with proper material selection to ensure corrosion resistance and longevity.

316L vs. 304 Stainless Steel: For superior corrosion resistance, especially in environments with chlorides

(e.g., from CIP cleaning chemicals), 316L ultra-low carbon stainless steel is the preferred choice.

304 stainless steel may be suitable for less aggressive applications but carries a risk of pitting corrosion in systems using chlorinated cleaners.

Seal Material : The sealing elements are critical wear points.

Common materials include:

PTFE: Offers excellent chemical resistance for a wide range of acids and alkalis.

EPDM Rubber: Ideal for steam sterilization (SIP) and hot water applications.

Silicone Rubber: Used for high-purity media.

2. Hygienic Design

A true sanitary ball valve must be designed to prevent contamination and allow for thorough cleaning.

Surface Finish: The internal surface roughness should be ≤ 0.8 µm to prevent bacterial adhesion and facilitate easy cleaning.

Advanced models can achieve an even smoother Ra ≤ 0.4 µm.

Zero Dead Legs: The Tri Clamp Ball Valve must be designed with a full-bore (full-port) design and minimal internal cavities to eliminate areas where product or bacteria can accumulate, which is crucial for CIP processes.

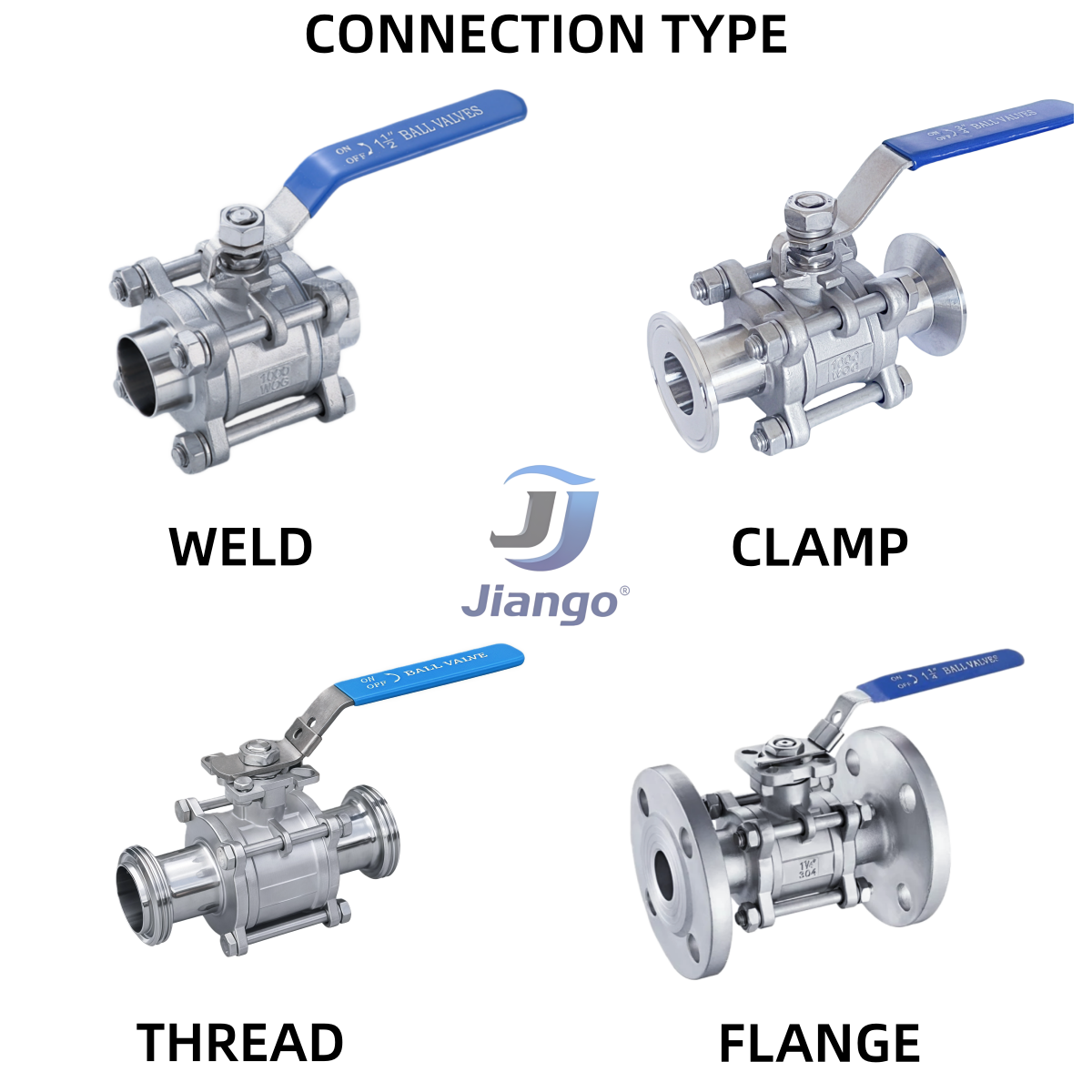

Connections: Choose from Tri-Clamp (quick-disconnect), Butt-Weld,Flange or Threaded (DIN 11851) ends based on your industry's standards and need for disassembly.

3. Technical Specifications & Certifications

Always verify that the Food Grade Ball Valve meets the required operational and regulatory demands.

Pressure & Temperature: Standard sanitary ball valves typically operate at pressures up to 1.0 MPa and temperatures from -10°C to 150°C. Ensure your selection fits within your system's parameters.

International Standards and Certifications: Compliance is non-negotiable for market access. Key certifications include:

3-A SSI: For the North American market, particularly dairy and food equipment.

CE Certifications: For the European market, ensuring compliance with hygienic design principles.

Other Standards: ISO, DIN, IDF, SMS, and ASME BPE are also widely recognized.

4. Actuation: Manual vs. Automated

The choice of actuation impacts control and operational efficiency.

Manual Operation: 316L Ball Valve Suitable for applications with infrequent operation.

Pneumatic Actuation: Ideal for high-frequency operation (e.g., >30 cycles per day) requiring fast response times (<1 second).

Electric Actuation: The best choice for precise control (with less than 2% open/close error) and for integration into PLC-controlled systems.

WENZHOU ANMAX is a leading manufacturer of sanitary fluid equipment, including ball valves, screw pumps, and sanitary pipe fittings. Specializing in 316L and 304 stainless steel products, the company serves the food, beverage, pharmaceutical, and biotech industries worldwide.

All products are designed to meet stringent international standards such as 3-A, ISO, and FDA requirements, helping clients achieve the highest levels of quality and safety.