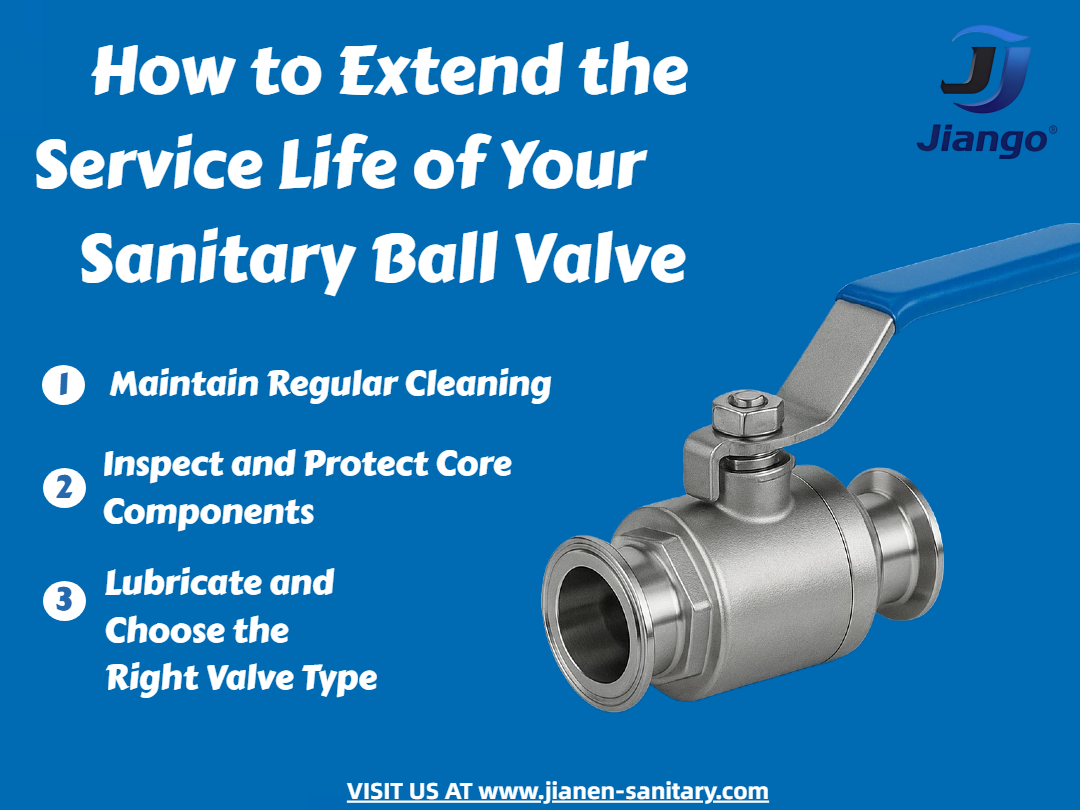

Extending the lifespan of a sanitary ball valve is essential for stable production in food, beverage, dairy, and pharmaceutical processing.

Here are three key steps to keep your stainless steel sanitary valve performing at its best:

1. Maintain Regular Cleaning

Perform consistent CIP/SIP cleaning to prevent residue buildup and protect the 316/316L stainless steel surfaces.

This reduces corrosion and ensures hygienic operation.

2. Inspect and Protect Core Components

Check PTFE seats, seals, and the valve body regularly to avoid leakage.

For tri-clamp, welded, or threaded sanitary ball valves, ensure connections stay tight to prevent vibration wear.

Use high-quality sanitary fittings, hygienic piping, and process equipment to further extend valve life.

3. Lubricate and Choose the Right Valve Type

Apply food-grade lubricant to reduce friction on moving parts.

For demanding applications, select a heavy-duty sanitary ball valve designed for high pressure and high temperature environments.

By following these steps and choosing trusted sanitary valve manufacturers,

you can significantly extend service life, reduce downtime, and improve production efficiency.