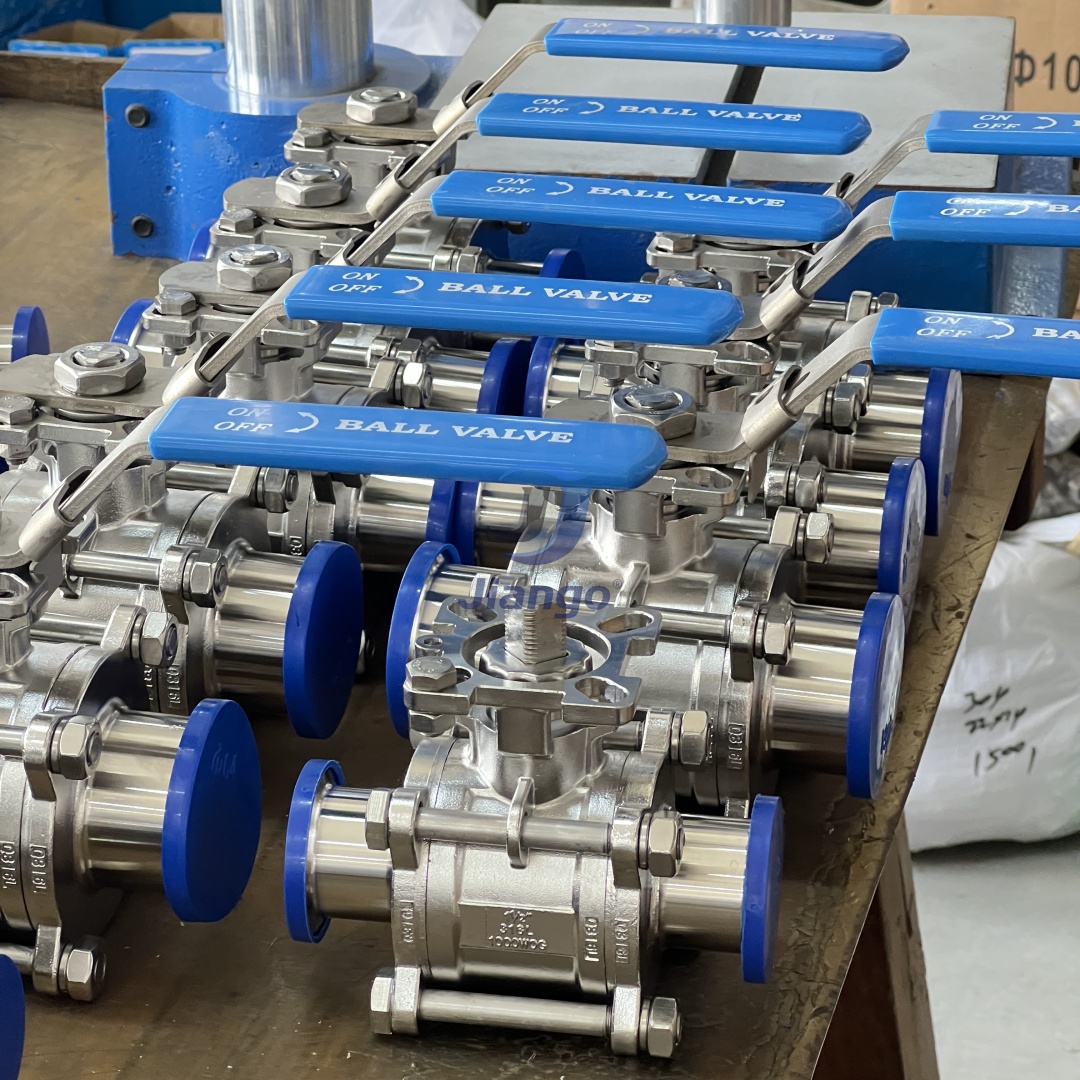

Proper maintenance of a sanitary ball valve is essential for ensuring stable performance in food, beverage, dairy, brewery, and pharmaceutical processing systems.

Here are the most effective daily maintenance methods to keep your stainless steel sanitary valve operating safely and efficiently.

These practices extend the service life of ball valves and minimize unnecessary wear and tear.

1. Perform Regular CIP/SIP Cleaning

1. Perform Regular CIP/SIP Cleaning

Daily CIP/SIP cleaning prevents product residue and protects the 316/316L stainless steel surface from corrosion.

This is crucial for hygienic operation and long-term durability.

2. Inspect Seals and PTFE Seats

Whether using a tri-clamp sanitary ball valve, welded ball valve, or threaded sanitary valve, stable sealing ensures safe operation.

Frequently check the PTFE seats, O-rings, and sealing components for wear or leakage.

3. Check Installation and Connections

3. Check Installation and Connections

Ensure all sanitary connections — including tri-clamp fittings, sanitary ferrules, and hygienic piping — remain tight to avoid vibration damage and premature wear.

4. Lubricate Moving Parts

Apply food-grade lubricant to the stem and internal moving parts to reduce friction and extend the service life of the hygienic ball valve.

By following these steps and selecting reliable sanitary valve suppliers, you can improve equipment reliability and reduce maintenance downtime.