In the food and dairy industries, choosing the right valve is crucial for both production efficiency and product safety.

Let’s take a closer look at the main differences between sanitary butterfly valves and ball valves.

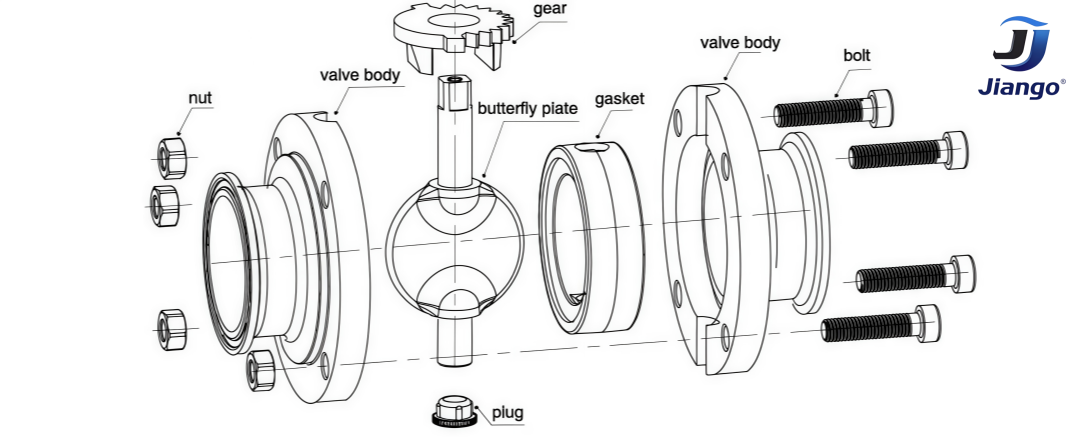

1. Operating Principle:

Sanitary Butterfly Valve:

Controls flow using a rotating disc.

Ideal for quick and frequent flow regulation.

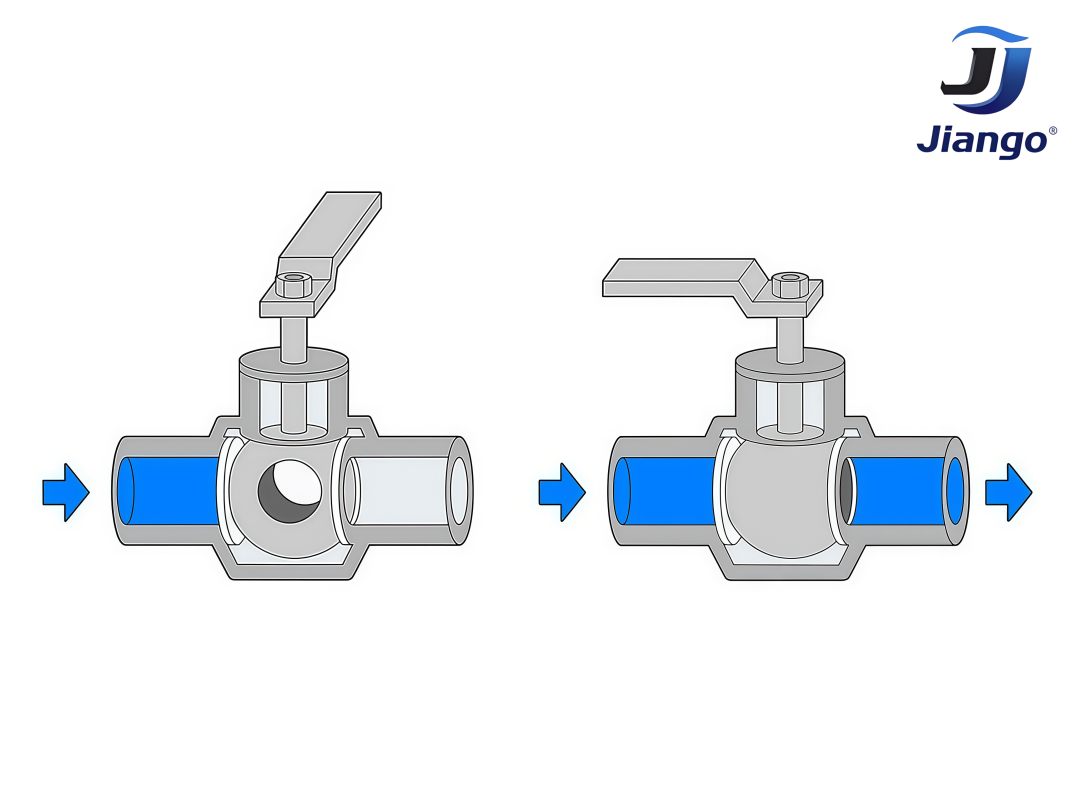

Sanitary Ball Valve:

Operates with a rotating ball with an opening.

Ensures sealing and is used for full flow shut-off.

2. Applications:

Butterfly valves are used in production lines where quick flow regulation is important (such as in milk, beer, and beverage production).

Ball valves are used in high-pressure systems and where sealing is critical.

3. Maintenance:

Butterfly valves are easier to maintain and more cost-effective.

Ball valves are more complex but provide reliable sealing.

Conclusion:

The choice of sanitary valve depends on the type of production. For flow regulation, a tri clamp butterfly valve is the better choice, while for reliable sealing, a three-piece ball valve is preferred.