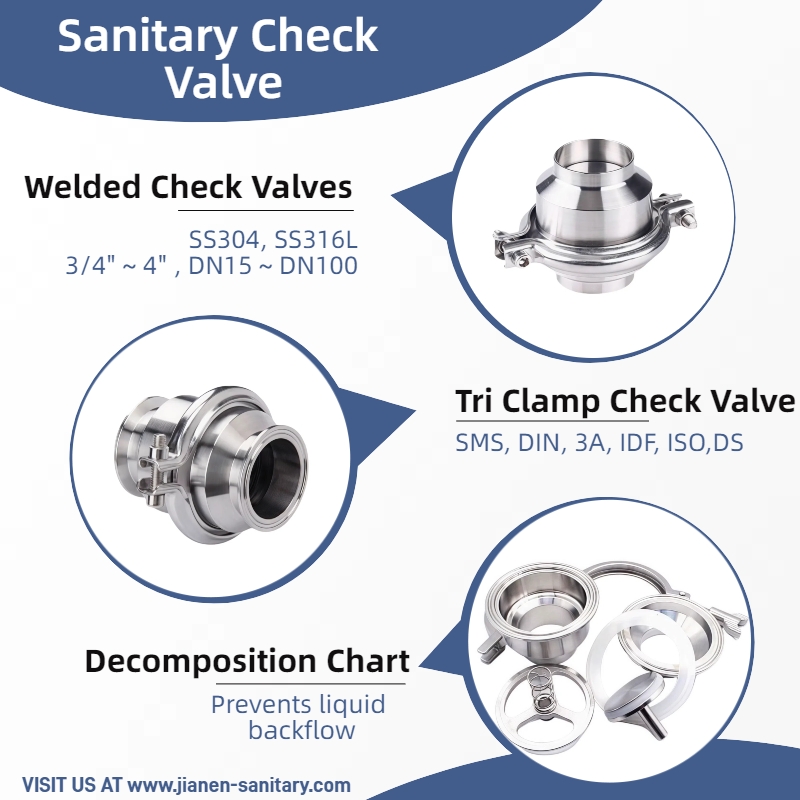

Sanitary Check Valves

Material : Stainless Steel 304 or 316L

Size : 1"-4",DN25-DN100

Connection : Clamp

100% tested and inspected

Operating Principle

The Sanitary tri-clamp check valve is a automatic and opens or closes based on the flow of product.

The valve opens when the pressure of the fluid exceeds the pressure to spring, When the two pressures are equalised, the valve closes, A stronger counter – pressure also makes the valve close

They allow flow in one direction only and prevent back flow.

It is quick and easy to disassemble for cleaning and servicing.

|

Name |

Sanitary tri-clamp check valve |

|

Material |

Stainless Steel 304 or 316L |

|

Size |

1"-4",DN25-DN100 |

|

Seal |

EPDM, Silicon, PTFE or on request |

|

Surface |

Ra16-32µin (0.4-0.8µm) |

|

Max Pressure |

10Bar |

|

Working Temperature |

-10°C ~ +120°C |

|

Way of Connection |

Tri-Clover/Clamp End,Butt Weld End |

|

Standards |

3A/DIN/SMS/RJT/ISO/IDF |

|

Package |

Foam bag/shrink bag-carton box-ply woodencase |

Precautions for Installing Sanitary Check Valves

Ball Check Valves

When installed vertically, the medium must flow from bottom to top, utilizing gravity to move the ball into and out of the seat.

For horizontal installation, the valve's curved section must remain vertical and form a 90-degree angle with the pipeline.

This design ensures free drainage while maintaining accurate ball positioning.

Disk Check Valves

Disk check valves cannot drain freely when installed vertically. Therefore, horizontal installation must be used to ensure free drainage capability.