Sanitary Stainless Steel Side Entry Single Bag Filter

Material : Stainless Steel 304 or 316L

Cartridges : 10"-40"

Max Operate Pressure: 10Bar

100% tested and inspected

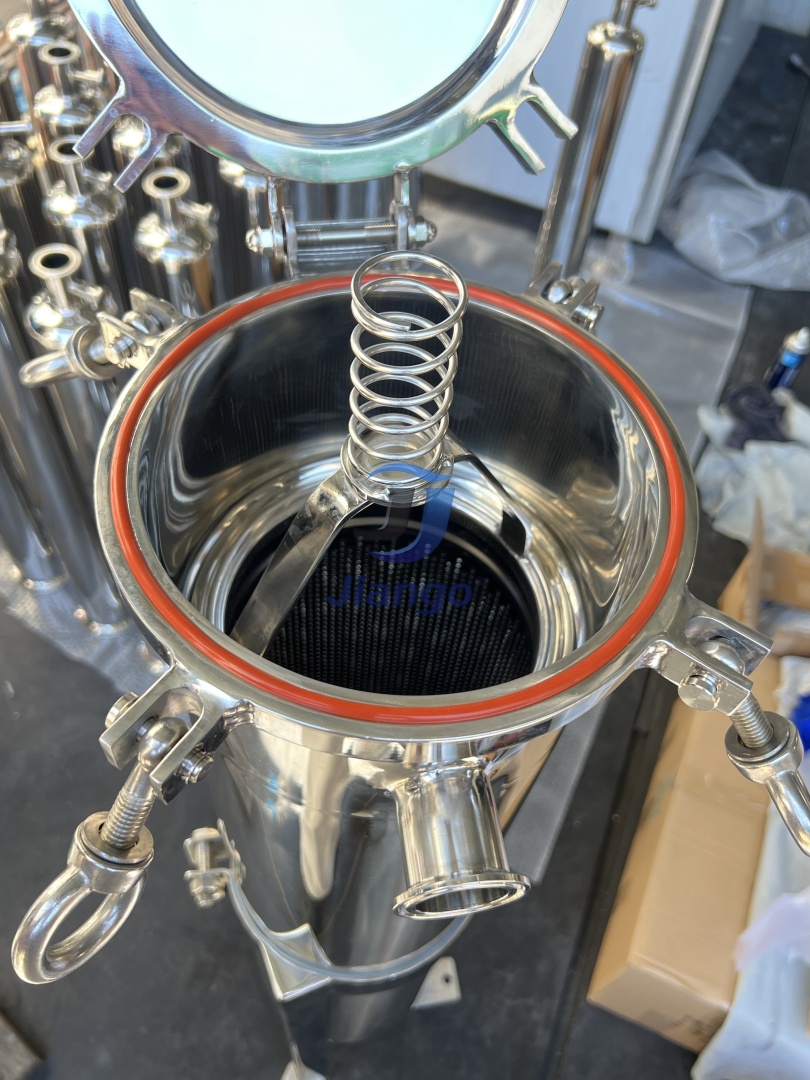

Side-entry bag filter with single filter bag is for some coarse filtration and pre-filtration process.

Liquid flows in and out after bag filtration, with impurities trapped in the bag. After replacing the bag, the filter can be used again.

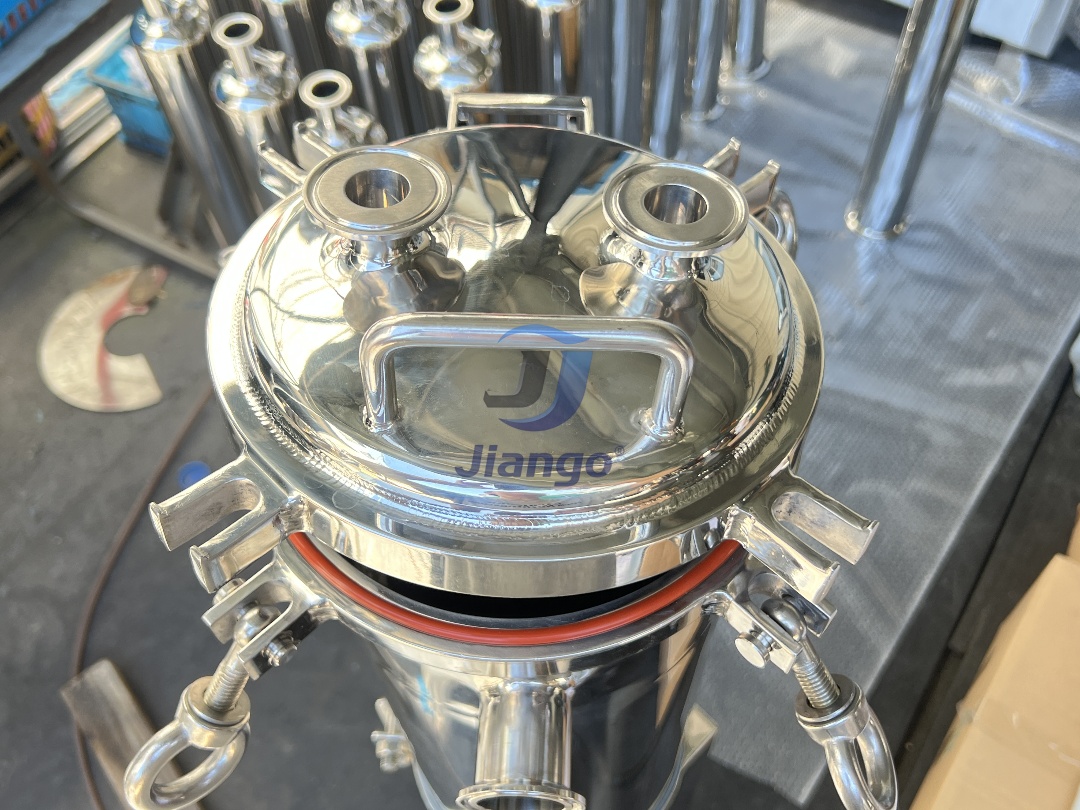

Side entry structure is a economical and reasonable design which can effectively save space of the filter.

Pressure ring and the spring ensure good seal between the filter and the filter bag.

With adjustable legs, the installation size can be adjusted according to the requirements of the particular spot.

|

Name |

Sanitary Stainless Steel Side Entry Single Bag Filter |

|

Material |

Stainless steel 304, 316L |

|

Cartridges |

10"- 40" |

|

Cartridges Connection |

226 Type and 222 Type, DOE Type |

|

O-ring |

EPDM, PTFE, Viton, Silicone |

|

Surface |

Mirror Polish,Matt Polish, Electrolytical Polish, Mechanical polishing,Acid Washing,Sand blasting |

|

Max. operating pressure |

10Bar |

|

Max. operating temperature |

150°C |

|

Way of Connection |

Tri-Clover/Clamp End,Thread End,Butt Weld End,Flanged |

|

Package |

Foam bag/shrink bag-carton box-ply woodencase |

Characteristics and Advantages

The bag filter has large flow rate capacity, small volume and dirt holding capacity.

Side-entry design for easy horizontal flow and simplified bag change-outs, which greatly improves the filtration quality.

The bag filter can withstand greater working pressure, low pressure loss, low operating cost and obvious energy saving effect.