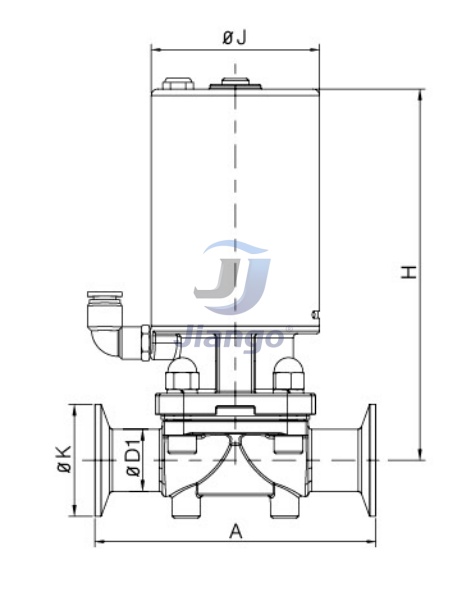

Pneumatic Diaphragm Valves with Tri-clamp

Material : Stainless Steel 316L

Size : 1" - 4" ,DN25 - DN100

Connection : Clamp

100% hydraulic tested / 100% inspected

The pneumatic diaphragm valve provides body seal as well as seat seal. There are no paths to outside environment so it is suitable for aseptic processes

When the sanitary diaphragm valve is closed, a pressure pad supports the diaphragm to move towards the sealing face on the body.

As the pressure plate moves, the diaphragm flexes and is forced down onto the seat area in the center of the body, thereby closing off the flow path through the body.

|

Name |

Pneumatic Diaphragm Valves with Tri-clamp |

|

Material |

Stainless steel 316L |

|

Size |

1"-4",DN25-DN100 |

|

Seal |

EPDM+PTFE double seal, EPDM or according to customers |

|

Standards |

3A/DIN/SMS/RJT/ISO/IDF |

|

Surface |

Ra16-32µin (0.4-0.8µm) |

|

Max Pressure |

10Bar |

|

Working Temperature |

-20°C ~ +150°C |

|

Way of Connection |

Tri-Clover/Clamp End,Thread End,Butt Weld End |

|

Package |

Foam bag/shrink bag-carton box-ply woodencase |

Correct installation can increase the service life of diaphragm valves and reduce maintenance time

1. Before installation, thoroughly clean and rinse the valve body to remove any dust, debris, or oil residue.

2. Select sealing materials that meet hygiene standards, such as silicone, EPDM rubber, PTFE, etc.

3. The selected connection method should be suitable for the application and necessary sealing measures should be taken to prevent leakage.

4. Select the appropriate valve location and direction.

5. After installation is complete, manually operate the test valve or test the actuator function.