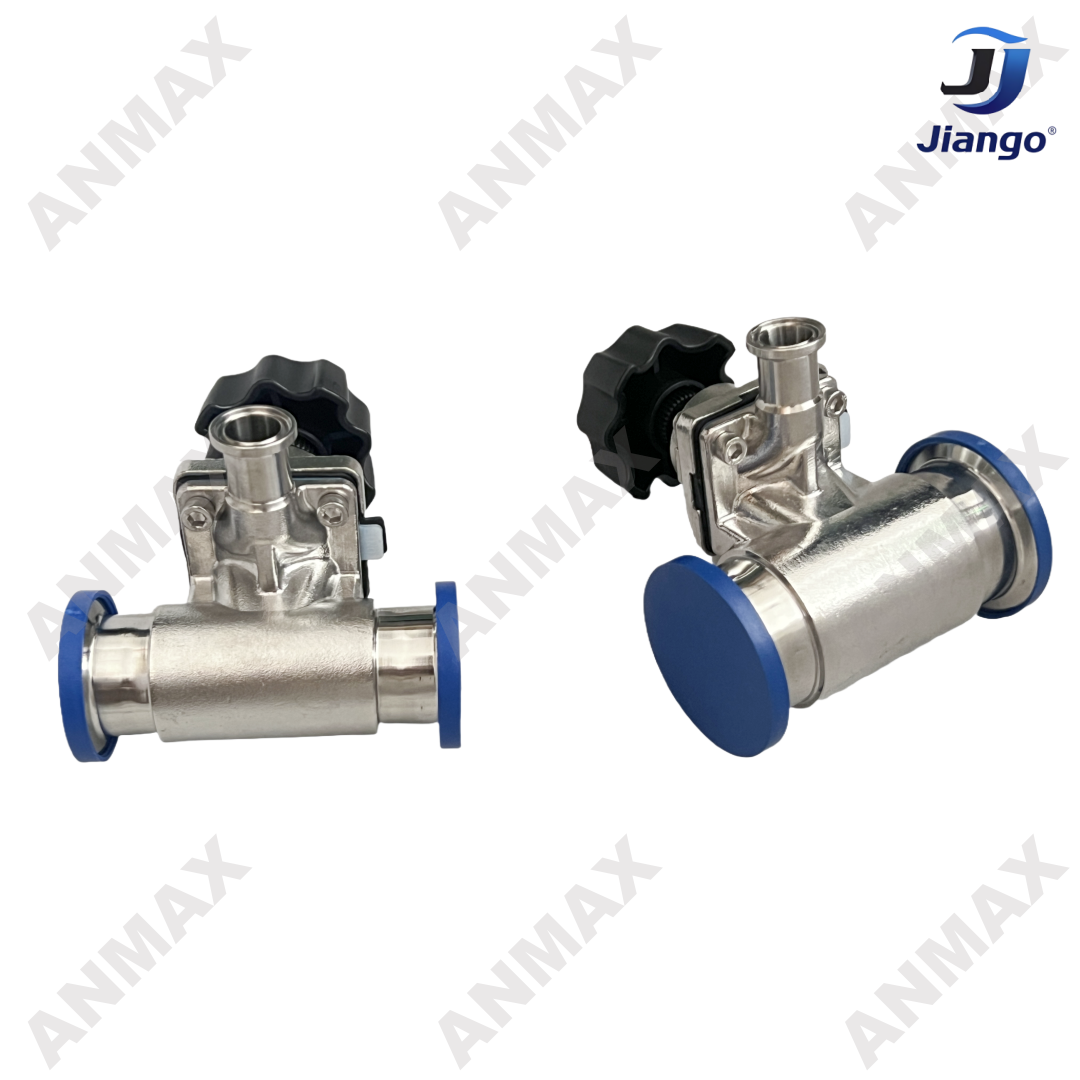

Reducing Tee Diaphragm Valve with Tri-clamp Ends

Material : Stainless Steel 316L

Size : 1/2" - 4" ,DN15 - DN100

Connection : Clamp

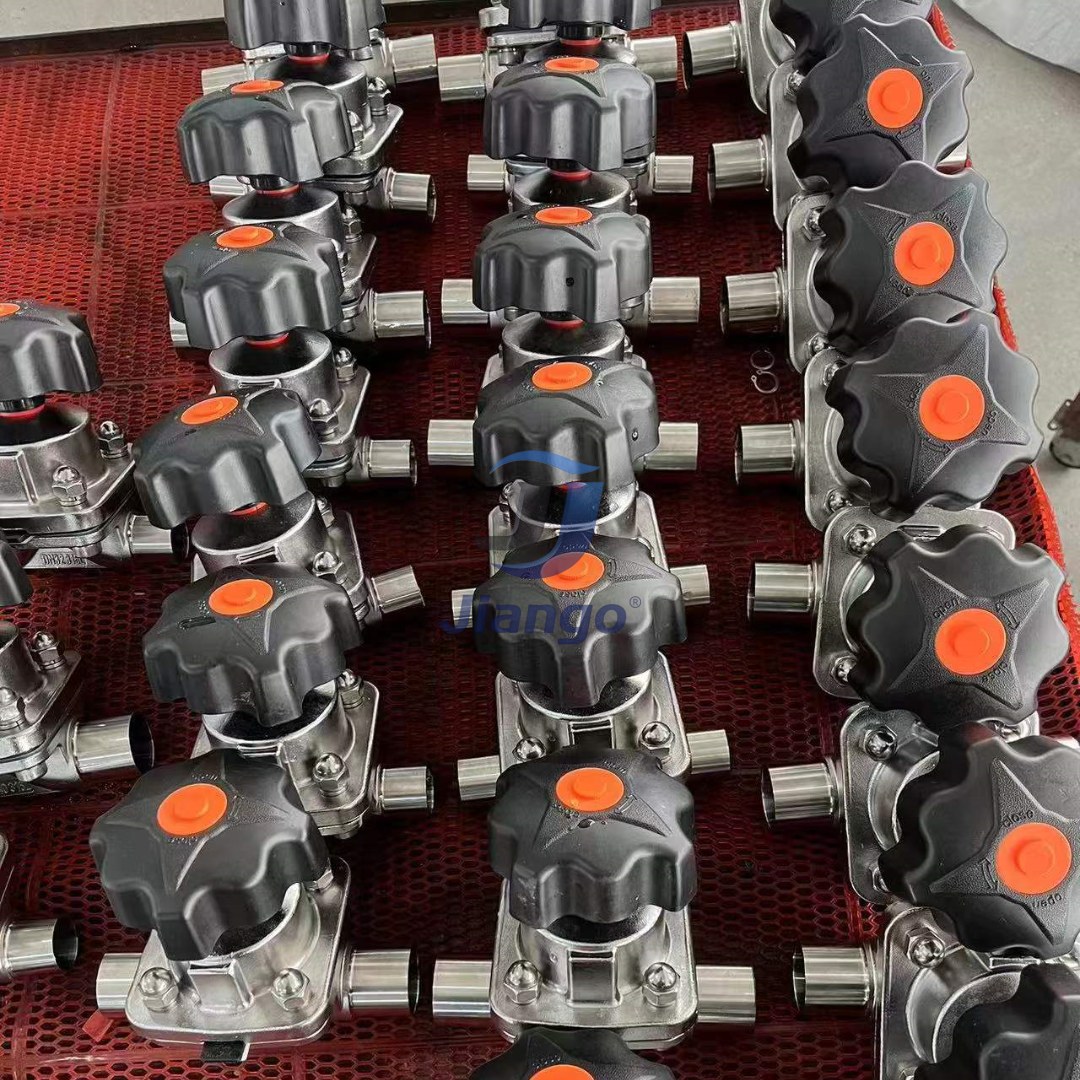

100% hydraulic tested / 100% inspected

Diaphragm valves derive their name from their flexible valve disc, which can interrupt fluid flow when it encounters the valve seat.

They utilize a pressure-sensitive diaphragm to provide the force required for opening, closing, or regulating the valve.

Unlike other valves, which feature a liner within the valve body, diaphragm valves operate directly through the diaphragm.

|

Name |

Sanitary Reducing Tee Diaphragm Valve Diaphragm Valve |

|

Material |

Stainless steel 316L |

|

Size |

1/4"-4",DN6-DN100 |

|

Seal |

EPDM+PTFE double seal, EPDM or according to customers |

|

Standards |

3A/DIN/SMS/RJT/ISO/IDF |

|

Surface |

Ra16-32µin (0.4-0.8µm) |

|

Max Pressure |

10Bar |

|

Working Temperature |

-20°C ~ +150°C |

|

Way of Connection |

Tri-Clover/Clamp End,Thread End,Butt Weld End |

|

Package |

Foam bag/shrink bag-carton box-ply woodencase |

Diaphragm valves excel in throttling applications and are highly hygienic due to minimal sediment or biofilm traps.

They effectively manage highly viscous, sticky, and particle-laden media.

Diaphragm valves have a low risk of stem leakage into the environment.

Their design isolates the operating mechanism from the fluid, reducing the likelihood of contamination.

The fluid does not interact with the operating parts, allowing maintenance and servicing without disrupting the pipeline.